Sandwich / Salad Containers

Introduction to Summary

Eco-friendly pulp packaging that emphasizes eco-friendly and organic elements

Sandwich / Salad Containers Success Story

1. Application Point

- Eco-friendly, organic sandwiches/salads are packed in natural environmentally friendly pulp containers.

- Our eco-friendly natural pulp containers can be used for showcase refrigerator storage, oven/microwave oven heating, dining-in, and taking-out of sandwiches.

- Our natural pulp containers are breathable, so they do not generate moisture at the bottom and do not decrease the freshness of the food within that would otherwise occur with condensation.

2. Application Success Stories

- A. Bakery Franchise Sandwich Product Packaging Success Story

- Bakery franchises, who suffer from a decrease in sales of sandwiches, hamburgers, hot dogs, burritos, and bagels in the winter, utilize our eco-friendly natural pulp packaging for showcase refrigeration, oven/microwave oven cooking, dine-in, and take-out applications to increase sales.

- In addition, companies that switched to ecostech's eco-friendly pulp packaging from synthetic resin packaging enjoyed an upgrade in product and brand image.

- B. Coffee Specialty Chain's Hot Deli Product Packaging Success Story

- One coffee specialty chain was considering the hassles of disposing conventional paper packaging when heating sandwich, bagel, and hot dog products and then repackaging them after heating when they were introduced to our eco-friendly natural pulp packaging. With the switch, they have enjoyed increased profits and higher table turnover rate.

- C. Salad Specialty Store Packaging Success Story

- Eco-friendly natural pulp packaging with special designs is used to emphasize the salad's green/organic characteristics and visual elements, improving the product's image.

3. Test Data

Test to measure the change in moisture content of packaged content in pulp and PE packaging

- A. Purpose

- To compare the change in moisture of packaged contents using contents (sandwiches) actually used on-site in conventional PE packaging and eco-friendly pulp packaging

- B. Experimental Methods

- 1) Sample Preparation

- Sample Name: Deluxe Sandwich

- Number of Samples: 10EA

- Time of Preparation: March 14, 2014 09:00

- Store Name: Gimje Bisabul Branch

- 2) Sample Storage Method

- After placing 4 sandwiches in separate containers, they were refrigerated at 7 °C before they were collected and analyzed for moisture content

- 3) Sampling Times

- 3~5g were collected after 0, 6, 12, 24, and 48 hours

- 4) Moisture Content Measurement

- Moisture content was measured using the dry weight loss method outlined in the General Test Methods of the Food and Drug Administration. (How to) Weigh accurately 3~5g of the sample on a preheated weighing dish and put it in a drier at 105 °C for 4 hours with the lid slightly open. After cooling in a desiccator for 30 minutes, weigh the amount of moisture.

- C. Experiment Performer

- Name of Institute: Wonkwang Health Science University, Department of Food and Nutrition

- Experiment Supervisor: Professor Ju Young Kim

- Experiment Period: March 14-16, 2014

- D. Experiment Results

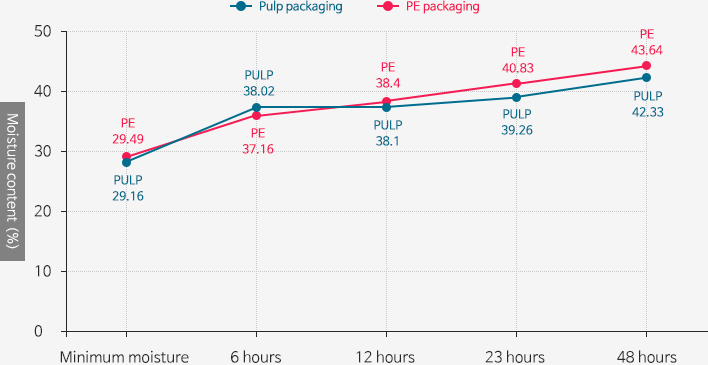

- Changes in moisture content of contents (sandwiches) in pulp and PE containers with respect to time

[Table 1] Moisture content at each time interval

- Comparison of moisture contents of packaged contents according to time elapsed

| Classification | Minimum moisture | 6 hours | 12 hours | 24 hours | 48 hours |

|---|---|---|---|---|---|

| Contents of pulp packaging | 29.16 ± 1.78 | 38.02 ± 2.14 | 38.10 ± 2.05 | 39.26 ± 1.87 | 42.33 ± 1.86 |

| Change(%) | ↑ 30.4 | ↑ 30.7 | ↑ 34.6 | ↑ 45.2 | |

| Change(%) | 29.49 ± 2.99 | 37.16 ± 1.09 | 38.40 ± 2.71 | 40.83 ± 2.14 | 43.64 ± 1.90 |

| Change(%) | ↑ 26.0 | ↑ 30.2 | ↑ 38.5 | ↑ 48.0 |

[Table 2] Comparison of moisture content according to sample

- E. Opinion

- The results of the experiment show that when using the same contents (sandwiches) that are manufactured and sold on-site, the contents of both pulp and PE packaging increase in moisture with respect to time. As shown in Table 2, there was no significant change in moisture content due to the presence of the salad and dressing that comes with the sandwich product. The increase in moisture content of the PE packaging after the 24-hour mark, which is higher than of the pulp packaging, is thought to be because of the lack of ventilation of the PE packaging compared to the pulp packaging.

- The increase in moisture content of the PE packaging after the 24-hour mark, which is higher than of the pulp packaging, is thought to be because of the lack of ventilation of the PE packaging compared to the pulp packaging. In the opinion of the experiment supervisor, both samples tested satisfied the requirements of the General Test Methods of the Food and Drug Administration and it is difficult to say that the change in moisture is due to the packaging.